SUPER PLAST COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SUPER PLAST COMPANY

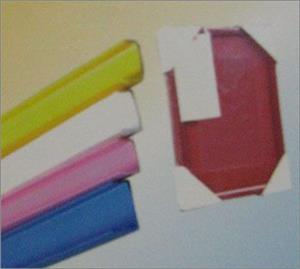

P.V.C. Sleeve

Description / Specification of P.V.C. Sleeve

We are involved in offering a wide range of P.V.C. Sleeve to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of P.V.C. Sleeve. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

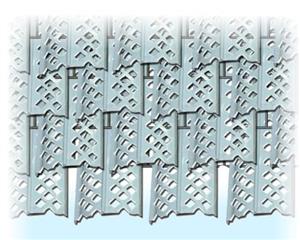

Perforated Stats

Smaller crossflow towers offers Perforated stats having surface and splash area equivalent to the timber section 1 ½ X ½” (highly used fill in wooden towers) giving an enhanced thermal performance. The diamond shaped perforations made out on the stats reduce the pressure drop considerably. The tower efficiency can be increased by up to 15% by offering a higher airflow for the same power and configuration or by reducing the power required to maintain the same airflow.

Older cross flow timber towers as well as some of the inefficiently designed newer once use rectangular timber slats for application as fill media. The rectangular timber slats provide very little in terms of enhanced surface area for the air and water to mix. Super plast has designed perforated slats to replace existing rectangular timber slats.

The efficient design of the SPC perforated slats cause the water droplets spread over the solid surface and perforated holes. The flowing water is held on the holes due to surface tension and forms a thin film. The water film formed over these rectangular holes has very low surface tension at its corners and thus a tendency to capture frequently. During this process of rupturing the water film is broken into small globules, thus providing maximum heat transfer.

These slats provide performance improvement over wooden rectangular fills and other perforated slats with round holes, over which, water film has relatively higher surface tension.

Better heat transfer rations due to the formation and quick rupture of water film on diamond shaped Perforations

Pack volume is reduced to 10% to that of timber slats

Increases the void volume in the tower, resulting in higher capacity

Economical and durable compared to wooden slats

No channeling of water

Perforations provide a considerable reduction in pressure drop resulting in lower power consumption and /or increase in air flow

Sixty Five M.M. Triangular Splash Bars

SPC manufactures triangular splash bars that serve as a cost effective, lightweight and longer lasting alternative to the PCC fills for large NDCT/IDCT. While these triangular splash bars can be manufactured in various sizes 20 x 20 x 30 mm, 35x 35 x 50 mm, 45 x 45 x 45 mm, 45 x 45 x 55 mm & the 60mm equilateral triangle installed to encounter minimum assistance to airflow is one of the more efficient splash fills design available.

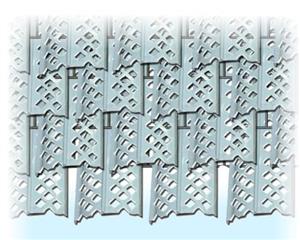

Cellular Drift Eliminators

Water droplets are separated from the air drift at the three direction change points on the drift eliminator. The SP-S130/146 drift eliminators provide a rugged cellular structure formed by the solvent bonding of sinusoidal shaped corrugated sheets. Individual S-shaped corrugated sheets are bonded with subsequent layers to create the structure. The entire area is thus divided into several smaller S-shaped mini zones.

FEATURES AND ADVANTAGES

- The modules are provided additional strength by the insertion of stiffener sheets at regular intervals.

- Cellular type drift eliminators offer the highest drift elimination efficiency while introducing a lower static pressure drop

- The eliminators can be assembled as well as cut at the field installation to ensure tight fit.

Boomerang Shaped Tube Settlers

FEATURES AND ADVANTAGES

- Most efficient tube settler design

- Can be transported in the form of loose tubes and hence saves transportation cost

- High specific settling area provided along with a high ration of wetted perimeter to wetted surface area.

- Lowest hydraulic radius giving high settling efficiency

- Needs a bottom support structure

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.